Home / TCT Saw Blades / Cut Off Blades Extra Thin Saw Blades (ATB)

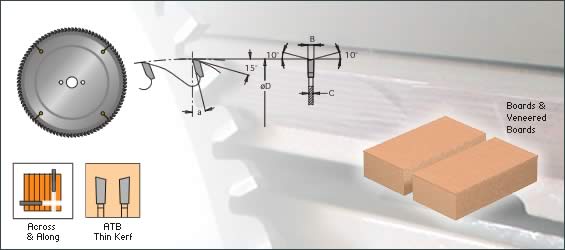

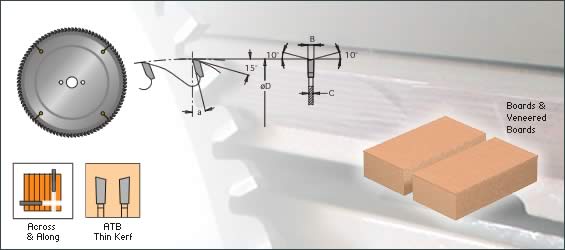

Cut Off Blades Extra Thin Saw Blades (ATB) Cut Off Saw Blades (ATB) Alternate Top Bevel

Cut Off Blades Thin Kerf Cut Off Saw Blades (ATB) Alternate Top Bevel Cut Off Blades is the act of cutting across the grain of the wood. It is much harder to cut in this direction, than to rip cut. For this reason, crosscutting is much slower than ripping. Crosscut blade cuts perpendicular to the grains of the wood and requires clean cutoff without jagged edges. The saw blade parameters should be chosen to best suit the cut. Under this includes: a large number teeth with about -2° to 8° hook angles, special tooth design like ATB, ATBR or HiATB, and slower circular saw speed settings.

Thin kerf circular saw blades are specialty blades, created for minimizing material waste in expensive hardwoods and hardwood plywood. They leave very thin width of the cut due to its actual tooth and plate width. While a typical circular saw kerf will be 1/8″ to 3/16″ (0.125″ to 0.187″), thin kerf blades cut a saw kerf of 3/32″ (equaling 0.093″) or less. While that 1/32″ of material may not seem like much, it can add up to be a great difference for materials which cost as much as $60.00 per board-foot. Blade can save at least 30% of the material comparing to the full kerf blades. The common application of thin kerf blades is for dimensional or engineered lumber where precise sizes mean a lot. Some of the advantages are better finish, less energy consumption by a circular saw and less waste. Thin kerf blades are available as rip cutting, crosscutting or combination saw blades, depending upon the need.

| Tool No. | Diameter | Teeth | Kerf | Bore |

| 8-80 THIN-E | 8" | 80 | .086" (2.2mm) | 5/8" |

| 10-100 THIN-E | 10" | 100 | .086" (2.2mm) | 5/8" |

| 12-120 THIN-E | 12" | 120 | .086" (2.2mm) | 1" |

More Product of TCT Saw Blades ... Cut Off Blades Thin Saw Blades (ATB) | RIP Saw Blades